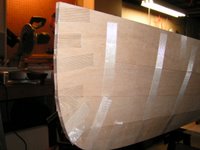

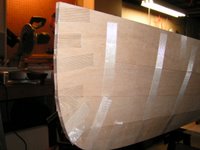

I am finally starting to see the fruits of my labours. I was starting to wonder if these long panels I have been joining would ever twist and bend into a kayak, but they really did fit together quite easily. The most challenging part was getting the first two panels together, particularly at the ends. That was due in large part to my decision to put my boat together without using the wire suturing that is normally employed. My thinking was that I would save time not having to drill the hundreds of holes for the wires and that I would not have to fill those same hole later. And, as my friend Doug pointed out, if it didn't work I only had to take off the tape and drill the holes; nothing to lose except a few hours of my time.

In place of the wire I used fiber tape every 15 cm (6") to hold the hull panels together. It worked much better than I expected and I managed to assemble the hull in less than 2 hours. The tape holds everything together amazingly well and yet it comes off very easily for removal and repositioning. The bow and stern ends were my biggest challenge because of all the stress created when the panels are twisted into shape, but I managed to tame them with some well placed tape and a couple of clamps. My next step will be to "spot-weld" the panels together every 15 cm (6") or as needed with a small amount of 5-minute epoxy. This hopefully will allow me to pull some or all of the tape so I can more easily apply the filler between the panels. Stay tuned !

I am finally starting to see the fruits of my labours. I was starting to wonder if these long panels I have been joining would ever twist and bend into a kayak, but they really did fit together quite easily. The most challenging part was getting the first two panels together, particularly at the ends. That was due in large part to my decision to put my boat together without using the wire suturing that is normally employed. My thinking was that I would save time not having to drill the hundreds of holes for the wires and that I would not have to fill those same hole later. And, as my friend Doug pointed out, if it didn't work I only had to take off the tape and drill the holes; nothing to lose except a few hours of my time.

I am finally starting to see the fruits of my labours. I was starting to wonder if these long panels I have been joining would ever twist and bend into a kayak, but they really did fit together quite easily. The most challenging part was getting the first two panels together, particularly at the ends. That was due in large part to my decision to put my boat together without using the wire suturing that is normally employed. My thinking was that I would save time not having to drill the hundreds of holes for the wires and that I would not have to fill those same hole later. And, as my friend Doug pointed out, if it didn't work I only had to take off the tape and drill the holes; nothing to lose except a few hours of my time.

In place of the wire I used fiber tape every 15 cm (6") to hold the hull panels together. It worked much better than I expected and I managed to assemble the hull in less than 2 hours. The tape holds everything together amazingly well and yet it comes off very easily for removal and repositioning. The bow and stern ends were my biggest challenge because of all the stress created when the panels are twisted into shape, but I managed to tame them with some well placed tape and a couple of clamps. My next step will be to "spot-weld" the panels together every 15 cm (6") or as needed with a small amount of 5-minute epoxy. This hopefully will allow me to pull some or all of the tape so I can more easily apply the filler between the panels. Stay tuned !

In place of the wire I used fiber tape every 15 cm (6") to hold the hull panels together. It worked much better than I expected and I managed to assemble the hull in less than 2 hours. The tape holds everything together amazingly well and yet it comes off very easily for removal and repositioning. The bow and stern ends were my biggest challenge because of all the stress created when the panels are twisted into shape, but I managed to tame them with some well placed tape and a couple of clamps. My next step will be to "spot-weld" the panels together every 15 cm (6") or as needed with a small amount of 5-minute epoxy. This hopefully will allow me to pull some or all of the tape so I can more easily apply the filler between the panels. Stay tuned !

0 Comments:

Post a Comment

<< Home